- Clearly define the project positioning.

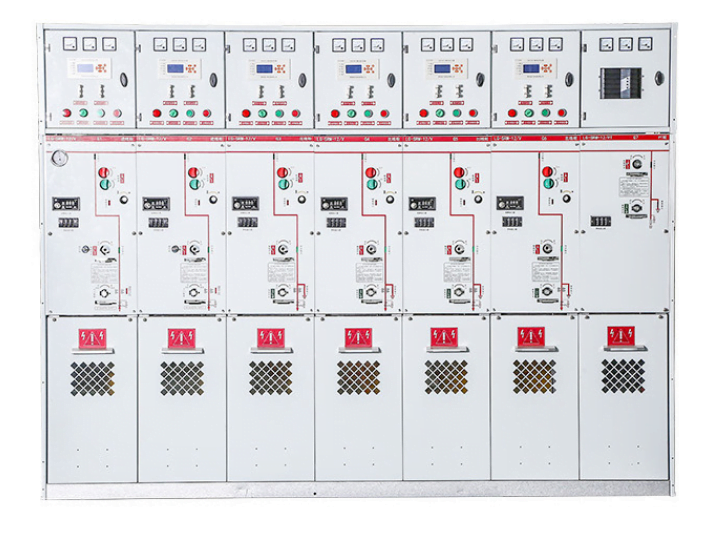

High-voltage switchgear is a complete set of composite products. Although there are hundreds of domestic manufacturers currently, the core components are still mainly imported products. If technical issues arise, equipment maintenance and replacement can be quite challenging. Therefore, when the budget allows, it is advisable to choose well-known brands as they typically have sufficient stock and higher efficiency in problem-solving when issues occur.

- Inspection of Qualifications

Before purchasing, it is necessary to request the factory test outline (or requirements) from the manufacturer. Generally, reputable manufacturers will have this. It should be clarified whether the main components are configured according to the drawings and whether specified brands, such as Siemens, Schneider, etc., have been chosen.

- Cabinet Material

High-voltage switchgear cabinets are relatively large, so the cabinet material has a significant impact on the price. Typically, imported aluminum-zinc plates are used for components and brackets, while door panels are made of high-quality steel plates from the 300 series.

- Arrangement of the Entire Cabinet

The arrangement sequence of the cabinet and the position of the operating surface are essential considerations for the manufacturer. They inform the construction of cabinet partitions, terminal guards, and busbar segment brackets. The layout drawing should align with actual site conditions, especially in indicating the operating surface direction accurately. Insufficient attention at the outset may lead to discrepancies upon equipment arrival, necessitating rework.

- Incoming and Outgoing Line Methods

There are generally two conventional methods for incoming and outgoing lines on switchgear: (1) cable chamber connection for incoming and outgoing cables, (2) outgoing lines are led out through wall sleeves on the top of the cabinet, connected to busbar bridges. Then, they are connected to overhead lines through wall sleeves. Some users introduce cables from the top of the cabinet, connect them inside, and then connect them to the top of the cabinet, using a separate safety net frame. While users provide one-line diagrams and standard schemes when placing orders, fully expressing the incoming and outgoing line methods is impossible. Users should specify technical agreements based on actual installation requirements on-site to avoid installation difficulties.

- Correct Selection of Circuit Breaker Breaking Capacity

On the one-line diagram, the selected circuit breaker indicates not only the circuit breaker model, rated working voltage, and rated working current but also the circuit breaker breaking capacity must be selected. Some user drawings do not specify the circuit breaker breaking capacity, which complicates manufacturers’ engineering design.The selection of breaking capacity should be based on the system short-circuit parameters. If the manufacturer does not understand the system short-circuit parameters, it is difficult to make the correct selection. Some user drawings blindly choose high breaking parameters without considering the system short-circuit parameters, resulting in unnecessary waste of funds. Correct selection of breaking capacity is important for safe operation and cost reduction.